I realized that I was being way over the top with the reply below so I’ll be more succinct in answering your reply. Please be advised that my question has nothing to do with the Yamaha 01x control surface and see below if you want to know why. I’ve almost completed an interface using an inexpensive 4 button footswitch to control Logic. The user can remotely control transport buttons, faders, mute, solo, record, monitor, pan and punch playback at the track level with the 4 button footswitch not to mention one heck of a lot button dancing. A footswitch like the FCB-1010 or the Nektar unit would be the way to go but from what I’ve read 4 buttons seem to be what people want…

Well, what you showed me is different from what I thought. I was referring to feedback of LED rings which are generally present on a Mackie MCU device. You are showing the MCU Scribble strip messages which are a special SysEx format.

>> Yes you are correct and I’ve included an example in the long message below.

Some DAWs that support MCU protocol have a way to zero the Pan knobs. I’m not sure if Logic does. Generally the message is an encoder push of the VPOT to reset to zero. We could send these messages to the DAW if you would like but we would need to figure out what trigger you need to send them and which pans you would like to zero out.

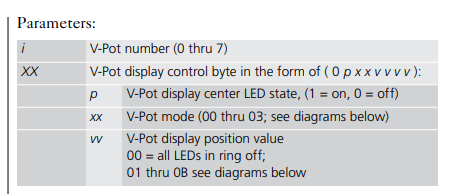

>> Logic does respond to push button encoder data if available. See below for a complete list. For track one the data is note on/off in the format of 90 20 7F then 90 20 00

The encoders themselves never send an absolute value (at least Mackie MCU only expects relative values) so you cannot tell the DAW with the knobs what values you want.

>> You’re probably right. In an earlier message I stated that I can accurately track the encoder position using decimal data in the form of 0 - 127. I then send the encoder what it wants as in 1 or 65 for CW or CCW rotation. This is also where I’m having an issue with telling the encoder what the position was upon a restart of the whole system or the same when creating valid preset data.

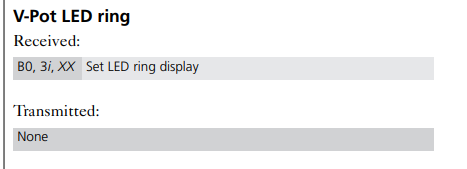

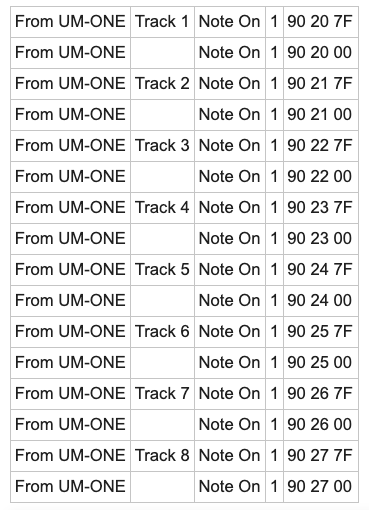

>> PS - I do have the hex data that will set the pan knob position and display value relative to the decimal data stream (0 - 127). The hex data is only used upon startup and storage as the encoder responds to the 1 - 65 relative movement data once given the starting point.

>> OK - now back to the question that I’d like to ask. Of the 128 hex code values that are relative to the positions of -63 through +64 of the pan knob I can use one translator to update 80 of the 128 values as the hex data is all numeric starting at 00 - 79. The related hex data is not linear at all regarding position data but is relative to the decimal stream of 0-127 so no big deal on relating them.

>> OK - So I lied and this is the root of my question. The 50 remaining hex code values are in an alphanumeric format as in 4F or 5D or 6A and I’m not able to create rules based on that structure or am I? If there is a way to accomplish that task then all would be so simple. As of now the only way I can think of is to hard code the alphanumeric values into the output of the translator which does work but I would have to create 50 translators to accomplish the task as well as reading through them all to find the match.

>> As mentioned this only occurs at startup and storage but I would probably store them whenever changing tracks so I don’t think the overhead would create problems for a relatively new computer system.

What type of controller is this that you have? Do the knobs support push function? Are the knobs absolute values?If not, we might be able to reset them with your switch. I will need to take a look at the Logic manual to see if it supports a ‘center push’ function.

>> I believe that all of the above have been answer with the above replies and definitely with my long winded banter below

So much for being succinct…lol

IMPORTANT: THE YAMAHA 01X CONTROL SURFACE WORKS FLAWLESSLY WITH LOGIC. MY QUESTION IS WITH HANDLING HEX CODE WITHIN THE RULES SECTION OF A TRANSLATOR AS DOCUMENTED ABOVE!

HI Steve and thanks for being welcomed back. I do find it ironic that I used to contribute to the forum well over 15 years years ago when forums were still referred to as BBS’s. My focus was changed due to a relationship. When I got back into it, an upgrade caused a loss of all previous postings so I had to start from scratch again. Just FYI…

If I misled you regarding this issue I apologize but I do need to reinforce that my questions have nothing to do with the Yamaha 01x control surface. Yamaha had the wherewithal 21 years ago to include firmware for the popular DAW’s of the day. The 01x’s main function was to act as a total recording system based on Yamaha’s Studio Master software offering. Although they provided firmware for Logic, Cubase, Sonar and Digital Performer they gave up on their proprietary interface called mLan (firewire) due to lack of interest roughly 10 years later. Perhaps you may have been affected as well as they also based the Motif Keyboard system on mLan.

The rotary encoders function in a ‘relative’ method and also provide other functionality beside ‘pan’. They do reset Logics pan control back to center when pressed. The following is the midi data that will reset Logic’s pan controls back to center. I was able to extract the sysex data when sweeping the pan control from full left to full right and included the data below. You had mentioned the sysex data and I think you at one time said that you are knowledgeable with sysex. I was attempting to see if there was a pattern but it’s all way beyond pay grade. At the end of the sysex data below I’ve included the midi data that was generated by a sweep from left to right but was not able to get any result when piping in back into the interface.

So much for being succinct with my message but since I had already extracted the data I thought I’d send it along for craziness as my grandmother used to say…