First thank you so much Steve (again) ![]() ,

,

i am still not sure if i did understand everything what you wrote here. I mean it seems that i organized everything ok so far, judging by your tutorial and what you wrote here. BUT i am not at a point, where i actually really need to deactivate and activate presets, i only prepared the project so far, that i can use these scenarios in the future, where they will become handy for sure.

So currently i dont deactivate or activate any presets by the outgoing ‘activate preset’ action and also dont use any of your mentioned checkmark boxes so far. Only used presets are active currently, but not set to ‘Always Active’.

So in theory a outgoing action with ‘Activate preset…’ should do nothing currently, because it points to a preset that already is active. However it does more then this, like i wrote previously, it stops processing further in the current preset and continues processing wherever the ‘Activate preset’ points to, much like a Goto ‘Label’ command. I just want to be sure now, if this is correct/true.

It would be a very nice feature for me, if i can use ‘Activate preset’ this way.

You might think ‘what is this guy doing’ ![]() , but i am still learning. Everything would be a lot easier, if i would not need to take care of so much things, like to store and print the value and to reflect the value with the LED rings. I would say its triple the afford vs. a ‘standard’ midi-controller that has no displays and no rings

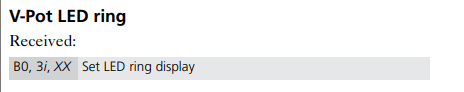

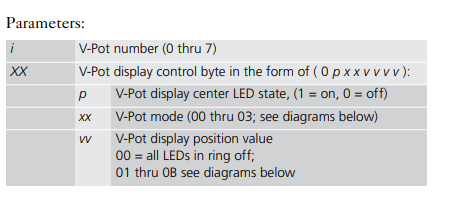

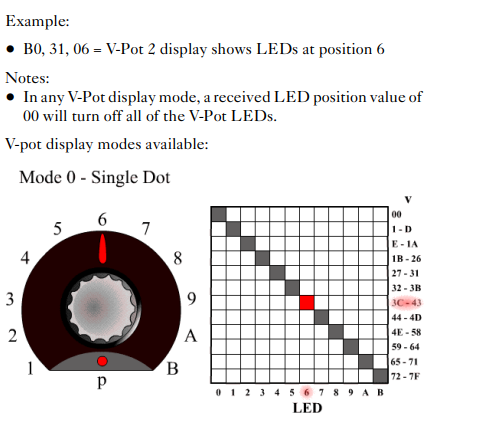

, but i am still learning. Everything would be a lot easier, if i would not need to take care of so much things, like to store and print the value and to reflect the value with the LED rings. I would say its triple the afford vs. a ‘standard’ midi-controller that has no displays and no rings ![]() . On the other hand, if everything works, the outcome was so much worth the work. Current state is, that page one seems to work like it should. There is just one thing that annoys me a lot and i want to get rid of. I will first try to hopefully solve this problem on my own.

. On the other hand, if everything works, the outcome was so much worth the work. Current state is, that page one seems to work like it should. There is just one thing that annoys me a lot and i want to get rid of. I will first try to hopefully solve this problem on my own.